« Columbus Day 2008 | Main | Groceries and green ash »

November 24, 2008

life in a workshop

DAY ONE: Monday, Nov. 24: These three pieces of furniture-in-the-making represent the third of three jobs I received deposits on in early July.

The first was the restoration of 21 antiques damaged in a flooded condo: 2 chests of drawers, a dining table, 8 chairs,various small tables and more; 84 days of continuous work. I finished around the first week of October, and the client moved back in happy with all her furniture.

The second job, for a former client, was to make an armoire similar to this antique I restored for her two years ago. Can I finish it by the end of the year?

I moved away from the job at hand - the three pieces at the top - several times due to 'jobs of opportunity', that is jobs that require mainly doing rather than thinking and doing, and I was saving it for when I had a clear mind and money in the bank.

The photo below is a mock-up of what are to be two nightstands for the client's master bedroom. The knob is temporarily held in place.

The logic-defying black desk with one leg is for the guest bedroom of the same client.

The desk is made of oak which has been coerced into becoming black with a black dye-stain, followed by black oil-stain. The clear finish over the two stains produced a really nice satin sheen; like polished slate. There isn't any paint on it.

Below: the sycamore drawer and the hand-carved foot is oak.

The design is my version of an Italian 'moderne' piece from the 1950's.

I'm almost finished with it.

THE NIGHTSTANDS

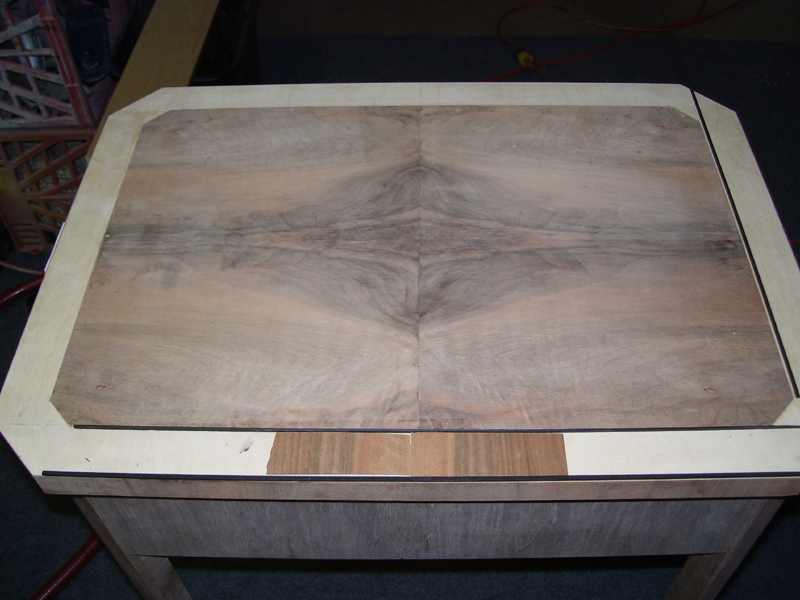

The nightstands will have a drawer, and a shelf below. The veneer is French walnut. They are companion pieces to this antique chest of drawers also of French walnut.

The top is a book-match of four pieces of veneer with a border of more French walnut outlined with ebony strips.

French walnut lumber was unavailable locally, and it took a trip, in late July, to a Pennsylvania importer to find a suitable board for the legs. The $300 board I bought had just enough material to get the right grain pattern and color for the front two legs of each table; the back legs got the less attractive grain pattern. I had to cut and paste to get the thicker dimension.

What I was after was solid wood to make the curved shape on the fronts.

The pieces are coming together now. I was just getting a grip on them the first of November when I got an offer I couldn't refuse. That job gutted the month.

I like to get projects like this to a more fully developed stage before I go all-ahead-full. A call today from one of the twisted knickers involved asked my favorite questions: "When is it going to be done?" "Why is it taking so long?"

So I'm moving the lever all the way forward.

Today, at the end of eight hours I have the black desk just about finished. The nightstands are fleshed out; not sure how much time I have in them to date; call it four days, including the eight hours for the Pennsylvania trip.

So let's just see how long it takes to go from here to completion.......

TUESDAY

Noon: Three hours to finish off the drawer and other details on the black desk. It's ready to go.

In projects like this for every problem solved new problems come up.

I managed to find the hardwood for the legs, but I didn't buy enough. Now the sides of the legs show an unattractive line where material has been glued up. I'm going to have to veneer the sides of the legs.

And the backs of the rear legs are visible from the front. At least two of those are going to require veneering to cover some unattractive grain swirls.

That task chewed up the day.

Ten hour day.

WEDNESDAY

Started early; ran the strip of ebony along the bottoms of the sides; made the dovetailed drawer parts; finished veneering the legs.

This job is technically being done out of turn, and it is in

violation of a ronpacifinewoodworkiing rule established in

1983: which states that ronpaci does not work through a middle

man and direct contact with the client is mandatory.

I have not met the client for this job. This is a problem. Clients have to fit my approved profile. They have to be vetted for their ability to withstand the ways and means of ronpacifinewoodworking.

I was busy when this came in. I put in a healthy bid, they agreed, and I let it go.

So here I am, the best fine woodworking effort of the year going to a stranger.

Veneered the bottom of the tops with two wide sheets of maple veneer. Both sides of a panel need to be veneered so it stays flat.

Eight hour day.

THURSDAY

Thanksgiving. Started late.

I've been in total isolation since Monday evening. The land line is on 'do not disturb', cell phone is turned off, in a pocket somewhere; wife is content, reading and nursing a cold; grandkids are with the other grandparents.

The sky is gun-metal grey. The shop is warm and the sound of Radio Olgiata is being broadcast from Rome through my pocket pc and out the speakers powered by two 12-volt marine batteries being lightly charged by one lonely 50-watt solar panel on the roof of my 1924 wood garage which will probably collapse under it's own weight in about 25 years just like me.

I'm working on the tops. They are an inch thick, two pieces of half-inch thick Baltic birch, glued together so the slight bow in the panels cancels itself out.

I did that and laid the book-matched centers on both tops last month.

Today I'm routing a groove around the main veneer; just over a sixteenth inch deep and exactly a sixteeth inch wide using the outside edge of the top as a guide.

- rip strips of ebony from a larger board on the bandsaw

- machine strips with a drum sander to fit into the groove

- cut 8 strips to length

- block sand ends to 22.5 degrees

- run glue into groove using a plastic hyperdermic device

- hammer strips into groove

- repeat for other top

The strips are oversize and stand proud to the surface making an edge to push against with the narrow pieces that make the border of french walnut.

The veneer for the border has a straight grain pattern in contrast to the broad grain pattern in the middle.

The color varies from plain orangy-brown to an area with black grain. The black in the wood is the premier feature of French walnut. The eboniste of Louis XIV loved it.

Laying the border starts at the centerline of the main four pieces on the top. I used the plainer area as the starting point, and tried to keep it logical as the pieces approached the corners.

I cut the strips with my new, specially sharpened, German veneer saw. I probably should have used my French veneer saw, but it's seen quite a bit of action.

- repeat steps for other top

I did some other things related to the drawers.

Turned out the lights at 11.

Twelve hour day.

FRIDAY

The thin ebony strip laid into the top is still proud of the

veneer on either side. I scraped it flat with a piece of steel

with a special edge... called a cabinet scraper, appropriately

enough. A very controlled way to remove material, unlike

indiscriminate power sanding.

Now with the router, I cut away the edge and glued on the ebony

border using tape stretched over the edge as a clamp to hold the strip in place.

Another 16 pieces.

- when dry, scrape flat

- sand all...carefully.

The veneer and inlay work is complete on the tops; each one has 64 bits of material.

It warmed up a little today, so I sprayed finish on the tops, sides, and legs. Now we're getting somewhere.

I prepared a table for the assembly. That will be the step of commitment.

Ten hour day.

SATURDAY, SUNDAY, MONDAY

Work, eat, sleep....a friend calls me a binge worker, with the implication of being obsessive, in the psychologically imbalanced sense.

But, I think craftspeople and artists get a pass on that. It takes a state of mind to do fine work. And small objects, like the ones I'm working on, demand greater attention to detail. Ringing phones, social lunches, inquiring minds, any intrusion knocks you off the tightrope.

Every mistake I make I can attribute to my mind drifting away from what my hands are doing. Like dropping a glass in the sink, immediate reflection will show you were thinking about something other than the glass and the sink.

I knocked a leg off my assembly table resulting in two dents, right on the front. Mind drift; thinking about some wisecrack to make to my decorator friend and the client.

Dents in wood can be magically steamed out with a hot iron and a wet paper towel.

Monday night: 8 days of concentrated effort. It took three 10-hour days to get a coat of finish on the parts, glue the legs to the sides, fit the bracing, make the panel under the drawer, and fix problems.

TUESDAY

Spent the day on the two shelves: Final fitting of the panels, applying the veneer with the dark stripe in the center to relate to the pattern on the top, gluing on the ebony edge, and spraying the finish.

I stopped at 6. I noticed my attention span was now depleted.

WEDNESDAY

Now approaching 100 hours on the two nightstands; I pulled the plug at 5:30, but went back at 7 and finished everything except the drawer fronts, fitting the drawers, and attaching the tops.

Ten days would have been a nice round number, but I'll settle for eleven.

THURSDAY

I couldn't decide on how to fit the drawer fronts to the legs which are set at a 45 degree angle. Under consideration was to cut a pocket into the top of the legs and have the drawer front with a normal square edge fit into the cutout area.

That would be a risky operation at this point, even though I knew how I was going to carry it off.

I had glued hardwood to the sides of the drawer fronts for this purpose.

In the end I cut the sides of the drawer fronts at 45 degrees to match the legs. But I left a small area at 90 degrees so it wouldn't create a knife edge, and to protect the veneer.

Here it is finished with a cherry veneer bottom:

I used the same veneer for the fronts and sides, and for the edges of the tops and shelves; always starting from the center and working out. The effect is the pattern reads vertically through all the parts.

The pattern on the top stands alone, unrelated to the rest.

THREE P.M. I stepped back for the first time, the last screw in place. The hours added up to exactly 100, counting Monday Nov. 24.

I can think of several more things that could be done; I can think of several things I would like to do over...basta, finito.

The exact flow of events for Saturday through Sunday is lost. I should have kept a record of what I did each day; though I did note the time.

One of the things that goes through my mind when I burn time like this is that at least there will be physical evidence of my effort.

The owner of the twisted knickers who found herself between the client and me came to see the 'finished' pieces. There were squeals of delight, hugging, photographs, and happiness. Knickers were tidied up.

After she had gone, I moved the three pieces to the back of the shop and covered them. They sat there for four days out of my sight, at least.

Delivery was the following Tuesday Dec. 9. The first thing we did after the nightstands were placed beside the client's bed was to set two giant lamps on them covering the main feature of the tops. They went to work.

They were a nice complement to the antique chest of drawers:

The black desk worked perfectly in the space, though kind of dwarfed by the big art. We are looking for a suitable bench to go with it.

It was reported that the client 'absolutely loved everything....it felt like Christmas,' she said.

And, I might add, how about that timely pre-holiday delivery.

Posted by ronpaci at November 24, 2008 7:12 PM